ABB接觸器吸合以及觸頭接觸問題原因

來(lái)源:http://www.haoyuanxb.com/ 日期:2022-05-30 發(fā)布人:admin

ABB接觸器吸合不正常

Abnormal closing of ABB contactor

ABB接觸器吸合異常是指ABB接觸器吸合過慢,觸點(diǎn)不能完全閉合,鐵芯發(fā)出異響等異?,F(xiàn)象。原因及解決方法如下:

Abnormal closing of ABB contactor refers to abnormal phenomena such as slow closing of ABB contactor, incomplete closing of contacts, abnormal sound of iron core, etc. The causes and solutions are as follows:

1)由于控制回路的供電電壓低于額定電壓的85%,電磁線圈通電后產(chǎn)生的電磁力很小,動(dòng)鐵芯不能快速吸附到靜鐵芯上,導(dǎo)致接觸器拉緩慢或拉不緊??刂苹芈返碾娫措妷簯?yīng)調(diào)整到額定工作電壓。

1) As the power supply voltage of the control circuit is lower than 85% of the rated voltage, the electromagnetic force generated after the electromagnetic coil is powered on is very small, and the moving iron core can not be quickly adsorbed to the static iron core, resulting in slow or loose pulling of the contactor. The power supply voltage of the control circuit shall be adjusted to the rated working voltage.

2)彈簧壓力不足導(dǎo)致接觸器吸合異常;彈簧反作用力過大,導(dǎo)致拉入緩慢;接觸彈簧壓力過大,使鐵芯不能完全閉合;觸點(diǎn)的彈簧壓力和釋放壓力過大,觸點(diǎn)不能完全閉合。解決方法是適當(dāng)調(diào)整彈簧壓力,必要時(shí)更換彈簧。

2) Insufficient spring pressure leads to abnormal contactor closing; The spring reaction force is too large, resulting in slow pulling in; The contact spring pressure is too large, so that the iron core cannot be completely closed; The spring pressure and release pressure of the contact are too large, and the contact cannot be fully closed. The solution is to properly adjust the spring pressure and replace the spring if necessary.

3)因動(dòng)、靜鐵芯間隙過大,活動(dòng)部分卡死,轉(zhuǎn)軸生銹或變形,導(dǎo)致接觸器吸合異常。加工時(shí)可將動(dòng)、靜鐵芯拆下檢查,調(diào)整間隙,清洗轉(zhuǎn)軸和轉(zhuǎn)軸。支撐桿,必要時(shí)更換附件。

3) Due to the large gap between the dynamic and static iron cores, the movable part is stuck, and the rotating shaft is rusted or deformed, resulting in abnormal contactor closing. During processing, the dynamic and static iron cores can be removed for inspection, the clearance can be adjusted, and the rotating shaft and shaft can be cleaned. Support rod, replace accessories if necessary.

4)ABB接觸器代理提醒,由于長(zhǎng)期頻繁碰撞,鐵芯板面不平整,沿疊片厚度方向向外膨脹。這時(shí)可用銼刀修整,必要時(shí)可更換鐵芯。

4) ABB contactor agent reminded that due to long-term frequent collision, the iron core plate surface was uneven and expanded outward along the lamination thickness. At this time, the file can be used for trimming, and the iron core can be replaced if necessary.

5)短路環(huán)斷,造成鐵芯發(fā)出異響。在這種情況下,應(yīng)更換為吸不吸或放不開的相同尺寸的短吸。吸不上力或吸力不足的原因不僅是機(jī)械故障,還有電源電壓過低、內(nèi)阻過大、線圈斷線等是造成此故障的主要原因。不釋放或釋放緩慢的原因是觸點(diǎn)彈簧失去彈性或彈性太大,觸點(diǎn)復(fù)位力不足,觸點(diǎn)焊接,鐵芯極面或?qū)Р塾形酃歌F芯、鐵芯閉合時(shí)的退磁氣隙減小等。

5) The short-circuit ring is broken, causing abnormal sound from the iron core. In this case, it shall be replaced with a short suction pipe of the same size that cannot be sucked or put away. The reason for the failure or insufficient suction is not only mechanical failure, but also low power supply voltage, excessive internal resistance, coil disconnection, etc. The reasons for non release or slow release are that the contact spring loses elasticity or is too elastic, the contact reset force is insufficient, the contact is welded, the iron core pole surface or guide groove has dirt, the iron core, the demagnetization air gap when the iron core is closed, etc.

ABB接觸器觸頭接觸不牢靠

ABB contactor contact is not reliable

接觸器的觸頭接觸不足會(huì)增加動(dòng)、靜觸頭之間的接觸電阻,導(dǎo)致接觸面溫度過高,使面接觸變?yōu)辄c(diǎn)接觸,甚至不導(dǎo)電。此失敗的原因如下:

Insufficient contact of the contactor will increase the contact resistance between the dynamic and static contacts, resulting in high temperature of the contact surface, making the surface contact into point contact, or even non-conductive. The reason for this failure is as follows:

1)觸點(diǎn)上有油漬、花朵和異物??捎谜河芯凭蚱偷拿薏疾潦?。

1) There are oil stains, flowers and foreign matters on the contacts. Wipe with cotton cloth dipped in alcohol or gasoline.

2)長(zhǎng)期使用,接觸面被氧化。如果是銀或銀基合金觸頭,在觸頭表面形成氧化層或在電弧作用下出現(xiàn)輕微燒傷和發(fā)黑不影響工作,可用酒精擦洗、汽油或四氯化碳溶液;表面燒焦不均勻,只能用細(xì)銼去除其周圍的飛濺物或毛刺。不要?dú)w檔太多以免影響聯(lián)系人的壽命。

2) After long-term use, the contact surface is oxidized. In case of silver or silver base alloy contact, the formation of oxide layer on the contact surface or slight burn and blackening under the action of electric arc will not affect the work. It can be scrubbed with alcohol, gasoline or carbon tetrachloride solution; If the surface is not burnt evenly, only use a fine file to remove the splashes or burrs around it. Don't archive too much to avoid affecting the life of contacts.

3)ABB接觸器代理人員認(rèn)為,電弧燒蝕造成缺陷、毛刺或形成金屬屑顆粒等。對(duì)于銅觸點(diǎn),如果燒傷程度較輕,可以用細(xì)銼修復(fù)不平整,但不允許使用細(xì)銼。用砂布打磨,避免石英砂顆粒殘留在觸點(diǎn)之間,無(wú)法保持良好的接觸;如果燒傷嚴(yán)重且接觸面低,則必須更換新的觸點(diǎn)。

3) ABB contactor agent believed that arc ablation caused defects, burrs or formation of metal chip particles. For copper contacts, if the burn degree is light, a fine file can be used to repair the unevenness, but it is not allowed to use a fine file. Polish with abrasive cloth to avoid quartz sand particles remaining between the contacts, which can not maintain good contact; If the burn is severe and the contact surface is low, the contact must be replaced with a new one.

4)運(yùn)動(dòng)部分受阻。拆卸、檢查卡住的部件并進(jìn)行相應(yīng)的處理。

4) Movement is partially blocked. Disassemble and check the stuck parts and handle them accordingly.

ABB接觸器吸合以及觸頭接觸問題原因就是這樣了,如果您想長(zhǎng)久且順利的使用下去,就要對(duì)該產(chǎn)品的內(nèi)容做充足了解,預(yù)防好問題的出現(xiàn)。更多信息就來(lái)關(guān)注網(wǎng)站www.haoyuanxb.com獲取!

This is the reason for ABB contactor closing and contact problems. If you want to use the product for a long time and smoothly, you must fully understand the content of the product to prevent problems. For more information, please visit www.jntongyu Com!

相關(guān)新聞

相關(guān)產(chǎn)品

電動(dòng)機(jī)保護(hù)用斷路器MS2X系列

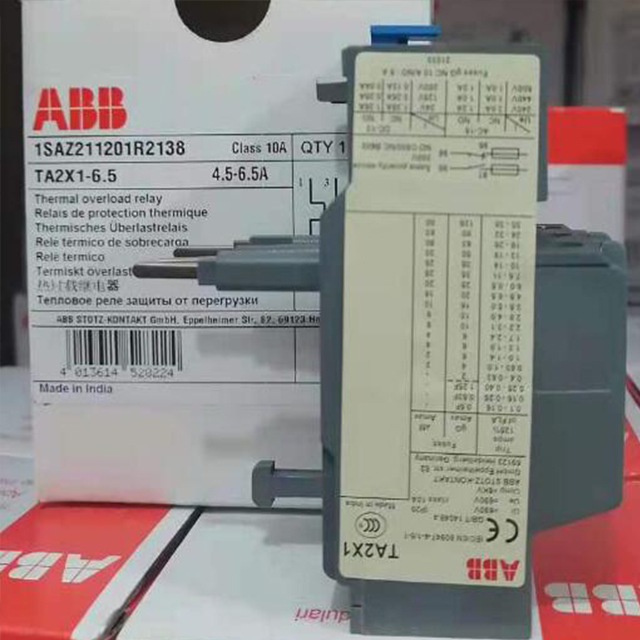

電動(dòng)機(jī)保護(hù)用斷路器MS2X系列  熱繼電器TA2X系列

熱繼電器TA2X系列  寬電壓接觸器AF系列

寬電壓接觸器AF系列  接觸器B系列

接觸器B系列

魯公網(wǎng)安備 37010402001012號(hào)

魯公網(wǎng)安備 37010402001012號(hào)